Industrial White Pigment Chloride Process Titanium Dioxide Cas No.13463-67-7

Sulfuric acid process titanium dioxide

Advantages: use cheap titanium ore (or titanium slag) and sulfuric acid as the main raw materials, of long-history technology, proven technique and low production cost.

Disadvantages: process, long process, serious pollution to the environment, low product quality stability

Chlorination process

Advantages: using the less impurities artificial rutile of 90% tio2 purity as the raw material, short process flow, production capacity easy to expand and continue, high quality.

Disadvantages: because of the monopoly of the foreign companies, it’s hard to bring in the foreign technology and equipment in China. Besides, due to the raw material of high content titanium dioxide ore, the production cost is relatively high and the process is hard.

Due to the different raw materials and production process, the product performance is different and has different requirements to the weather resistance, hiding power, aesthetics and dispersion titanium dioxide. So the clients should choose titanium dioxide of different quality based on their needs.

Specifications:

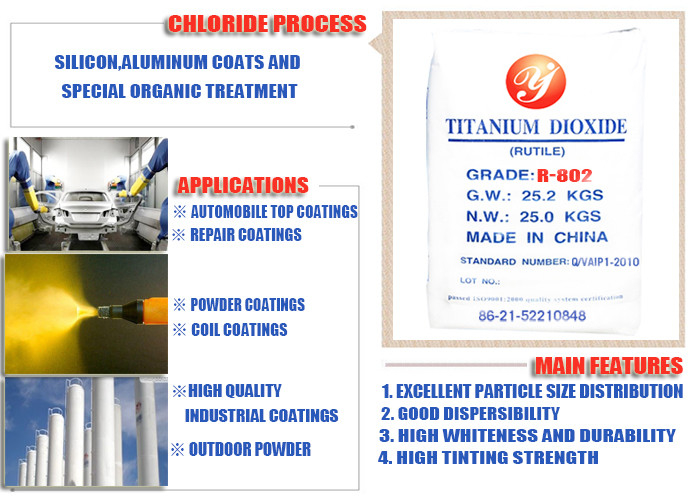

Liangjiang Brand R802 is chlorination process Rutile titanium dixoide,which is treated by Sio2, Al2O3.

It is designed as a universal type.

Produced by chloride process and surface wet treated by inorganic metal oxides,

and special organic chemicals, R-802 is a general titanium dioxide pigment.

It has excellent particle size distribution and durability, good dispersibility,

high whiteness,tinting strength and hiding power.

Basic data:

|

Chemical Name

|

Titanium dioxide(TiO2)

|

|

CAS No.

|

13463-67-7

|

|

EINECS No.

|

236-675-5

|

|

ISO591-1:2000

|

R2

|

|

ASTM D476-84

|

III, IV

|

|

Appearance

|

White powder

|

|

BET

|

3.9 g/cm3

|

|

Density

|

0.7~1.0 g/cm3

|

|

Surface treatment

|

Silicon, Aluminum coats and special organic treatment

|

Typical technical index( Standard:Q/VAIP1-2010)

|

Index

|

R 802

|

|

TiO2 %

|

≥91

|

|

Surface treatment

|

Si, Al

|

|

L*(acrylic paint system)%

|

≥95

|

|

B *(acrylic paint system)%

|

≤0.35

|

|

Whiteness(acrylic paint system)%%

|

≥90

|

|

Hiding power(acrylic paint system)%

|

≥94

|

|

Relative tinting strength(acrylic paint system, comparison with R902+)%

|

≥96

|

|

Oil dispersibility H

|

≥6.0

|

|

Oil absorption g/100g

|

≤21

|

|

PH value of water suspensions

|

6-8

|

|

Resistivity of water suspensions (Ω.m)

|

≥65

|

|

105℃ volatile%

|

≤0.5

|

|

Redidue (45µm sieve) %

|

≥0.1

|

|

Whiteness (compared to sample)

∆L*( samples- standard samples)

∆s=(∆a2+∆b2)0.5

|

Unlower

≥-0.3

≤0.5

|

Description:

1, Liangjiang Brand rutile titanium dioxide R802 introduced foreign advanced chloride process

technology for the manufacturing of Titanium Pigment,mainly manufacturing chloride process

rutile titanium pigment (referred as R type), which is very important white pigment and

ceramics glaze with excellent performance.

It also has excellent whiteness, tinting strength, hiding strength, weather resistance, heat resistance ,

chemical stability , especially no toxicity compared with other white pigments, and is widely used

in the following industries: coatings , plastic, paper making, printing ink, chemical fiber,

enamel, rubber, and cosmetics etc.

Applications:

1. Characteristic requirements for titanium dioxide in coatings and paints

|

Item

|

Building Coat

|

|

Normal temperature drying enamel paint (Little porcelain paint type)

|

emulsion coatings

|

|

Outdoor

|

weather resistance, Hiding power, aesthetic property

|

weather resistance, Hiding power, aesthetic property( Little outdoor)

|

|

Indoor

|

Hiding power, aesthetic property

|

Hiding power, aesthetic property

|

|

Item

|

Industrial Coat

|

|

automobile

|

home electrical appliances

|

|

Finish coat

|

weather resistance, Hiding power, aesthetic property , dispersibility

|

Hiding power, aesthetic property

|

|

floating coat

|

weather resistance, Hiding power, dispersibility

|

|

primer coat

|

dispersibility

|

Coatings industry consumes most qty of titanium dioxide, especially the rutile type. The global coating industries occupy 58% - 60%, mainly because the aspects of the performance is much better than the other white pigments. So the coating using by titanium dioxide is much higher than ordinary filler, because titanium dioxide is an integral part of in the coating, covering and adornment, its role is not only more important is to improve the physical and chemical properties of paint, bust also to improve the mechanical strength of the coating, adhesion, anticorrosive, light and weather resistance.So during of the production of coatings, It’s reasonable for us to choose the suitable type and specs!

2. Titanium dioxide quality requirements for plastic, PVC and masterbatch

|

Items

|

Performance

|

|

Hiding power

|

Lighter and thinner plastic products can be produced using tio2 of good hidinding power

|

|

Whiteness

|

Decide the appearance of the white or light color palstic products

light color or white color

|

|

Dispersibility

|

Affect the production cost of plastic products as bad dispersibility affects the smoothness and brightness

|

|

Weather resistance

|

The outdoors plastic products and plastic doors and windows require the weather resistance of tio2

|

|

Machinability

|

Titanium dioxide machinability is the vital key to the production efficiency and cost in the production of white masterbatch (especially the concentration variety)

|

|

Performace impact

|

Titanium dioxide volume of addition can affects the quality of the plastic products, especially in the condition of larger addition

|

Plastic is the second largest parts for titanium dioxide, occupying about 20% of the total world titanium dioxide demands, There are more than 50 brands belongs to plastic specials in the world 500 barands. Requirements for plastic, fine particle, good dispersion performance;Good heat resistance and light resistance,During the heat and the plastic forming process , the finished product does not change color in sunlight exposure and use process. Most of the particle size in plastic is fine. In the plastics, to join titanium dioxide can improve the heat resistance of plastic products, light fastness, weather resistance, make the plastic products to improve the physical and chemical performance.The strong mechanical strength can extend their life!

The effect of titanium pigment in the plastics industry mainly has two aspects, one is used as the basic white pigment, provide cover (white color); the second is to block uv light, used as uv screen disadvantages agent, used for outdoor plastic products to provide a good weatherability. For the Common plastic,it does not require the weatherability, focuses

More on the paint performance requirements.

Due to the characteristics of palstic products, When choosing different, should be taken into account in accordance with the technical requirements of plastic products, mainly to choose anatase or rutile, not same as the coatings, inks, paints.

3, Titanium dioxide compared with other kinds of white pigment :

|

Name

|

Relative Density

|

Refractive index

|

Tint reducing

|

hiding power

|

|

Reynolds number

|

relative value

|

|

Tiatnium dioxide rutile Chlorination process

|

4.0

|

2.85

|

1800

|

105

|

105

|

|

Tiatnium dioxide rutile sulfuric process

|

4.2

|

2.76

|

1650

|

100

|

100

|

|

Titanium dioxide anatase

|

3.91

|

2.55

|

1270

|

77

|

78

|

|

Barium sulfate

|

4.5

|

1.64

|

|

|

|

|

zinc oxide

|

5.6

|

2.02

|

200

|

12

|

14

|

|

lithopone

|

4.2

|

1.84

|

260

|

16

|

|

|

BasicLeadCarbonate

|

6.1

|

2

|

150

|

9

|

12

|

|

zinc sulfide

|

4

|

2.37

|

660

|

40

|

39

|

4. Titanium dioxide anatase, titanium dioxide antase coated, titanium dioxide rutile sulfuric process, titanium dioxide rutile chlorination process:

|

|

Titanium dioxide anatase

|

Titanium dioxide antase coated

|

titanium dioxide rutile sulfuric process

|

titanium dioxide rutile chlorination process

|

|

Powder type

|

Indoor powder

|

Indoor powder

|

Indoor /outdoor powder

|

Indoor /outdoor powder

|

|

Usage amount

|

big

|

seldom

|

big

|

little

|

|

Dispersibility

|

bad

|

good

|

good

|

good

|

|

Hiding power

|

bad

|

bad

|

good

|

excellent

|

|

Surface properties

|

bad

|

good

|

good

|

good

|

|

Fluidity

|

bad

|

good

|

good

|

good

|

|

Anti yellowing

|

bad

|

bad

|

good

|

excellent

|

|

Color stability

|

bad

|

Medium

|

better

|

excellent

|

This table shows the Liangjiang Brand chlorination process rutile titanium dioxide R920 has the highest refractive index, the highest hiding power (opacity) and achromatic force, bright whiteness, high gloss and good dispersion.

2, Comparation of chlorination process VS. Sulfuric acid process rutile titanium dioxide produced by Liangjiang:

We aspire to be the world's leading chemical raw materials supplier, showing the excellent value of products made in China!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!